Drill masts

AVD Drill masts

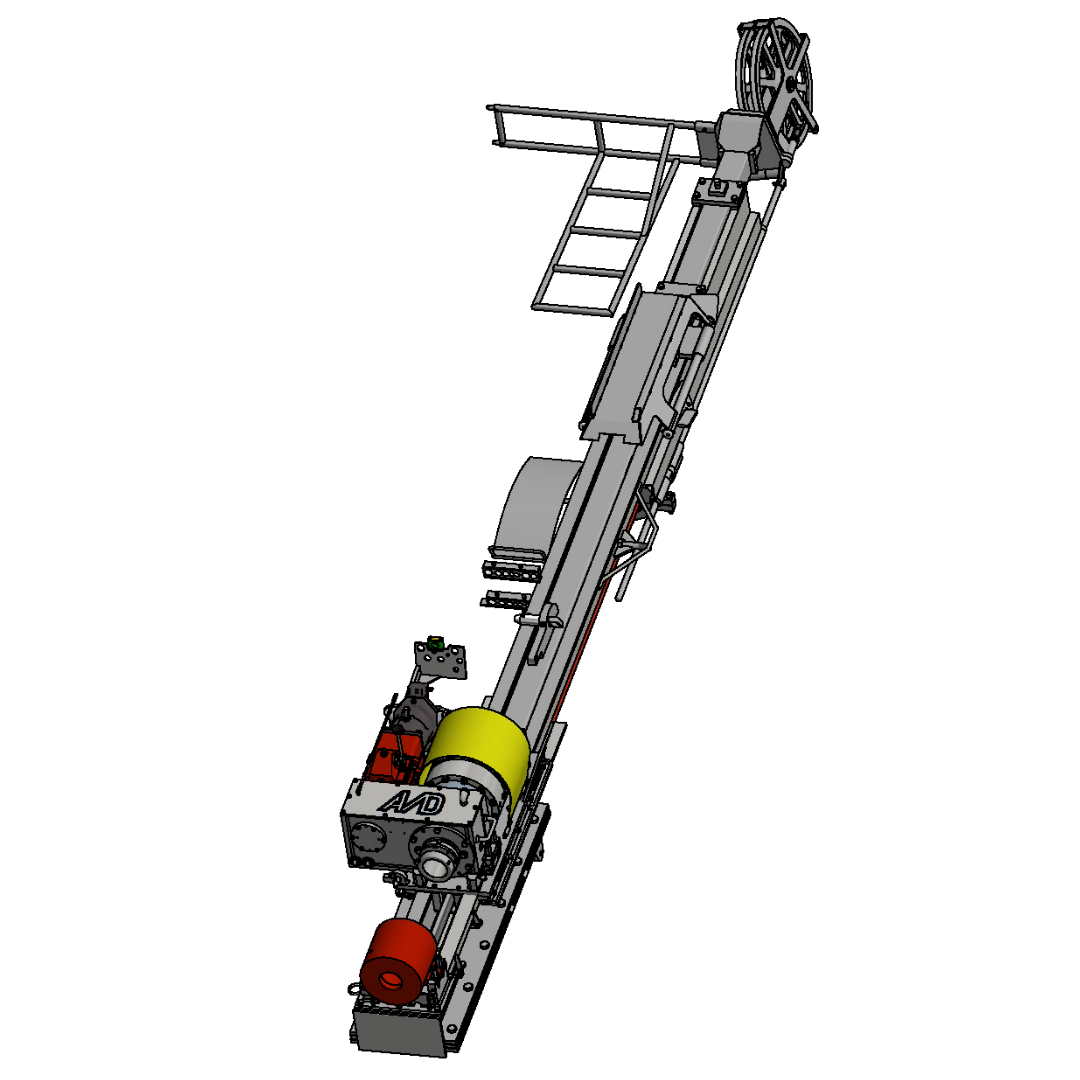

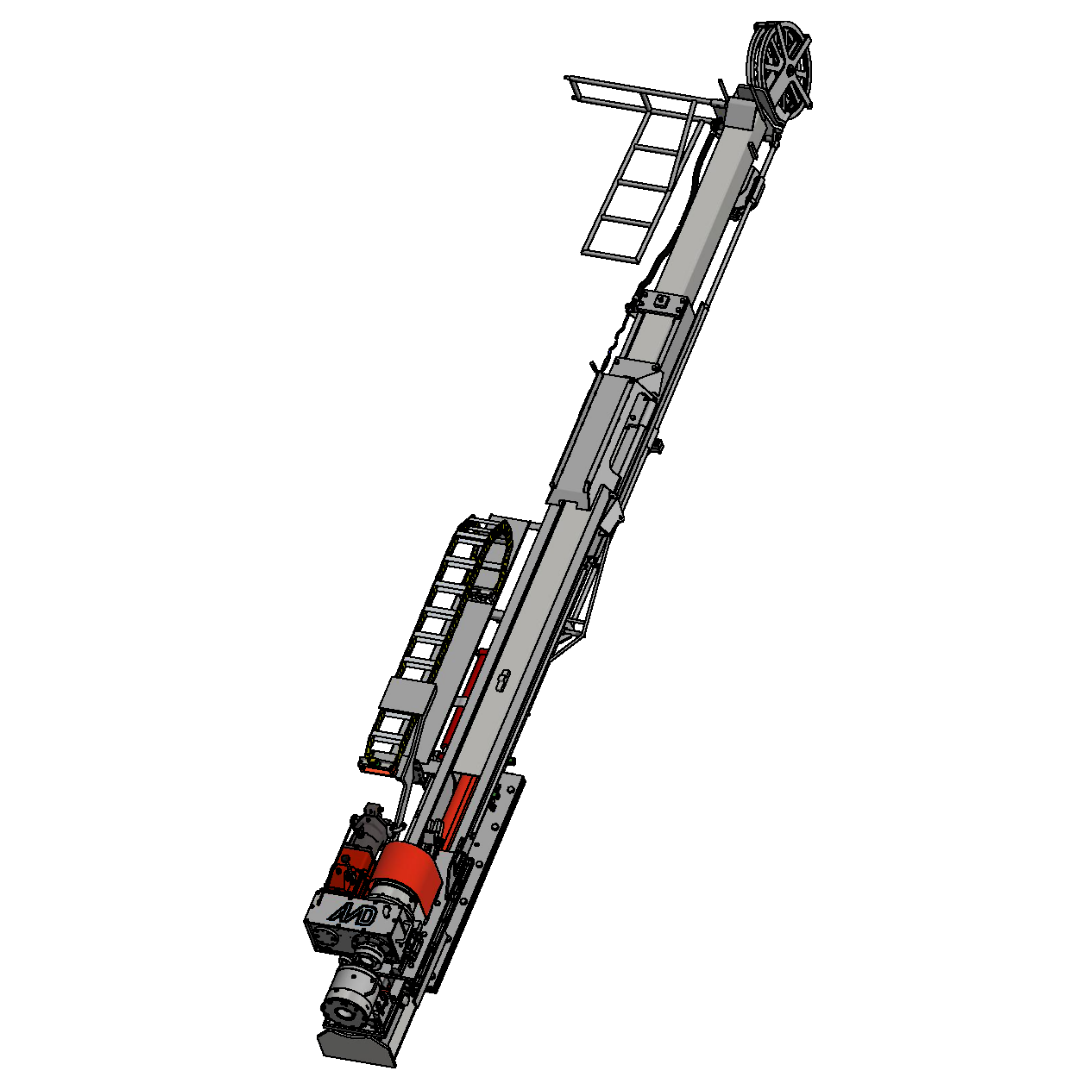

AVD ™ drill rigs are among the most robust in their class. Their superior design to the industry standard makes them a component that can be trusted for a long time. AVD ™ drill rigs also offer several options that make them easier to use and more reliable.

ROBUST

Fabricated in-house, the welded and machined beams from the AVD drill mast made with thicker steel plates make it the most robust mast in its class. Tested beyond the advertised rating.

RELIABLE

Over-designed to minimize the forces distributed in the plates, slides and bolts for a superior lifetime and lower maintenance required.

EASY

The design of the AVD drill masts is thought out very simply, thus favoring the training of new drillers.

SAFE

Critical structural welds are certified by an independent laboratory every time.

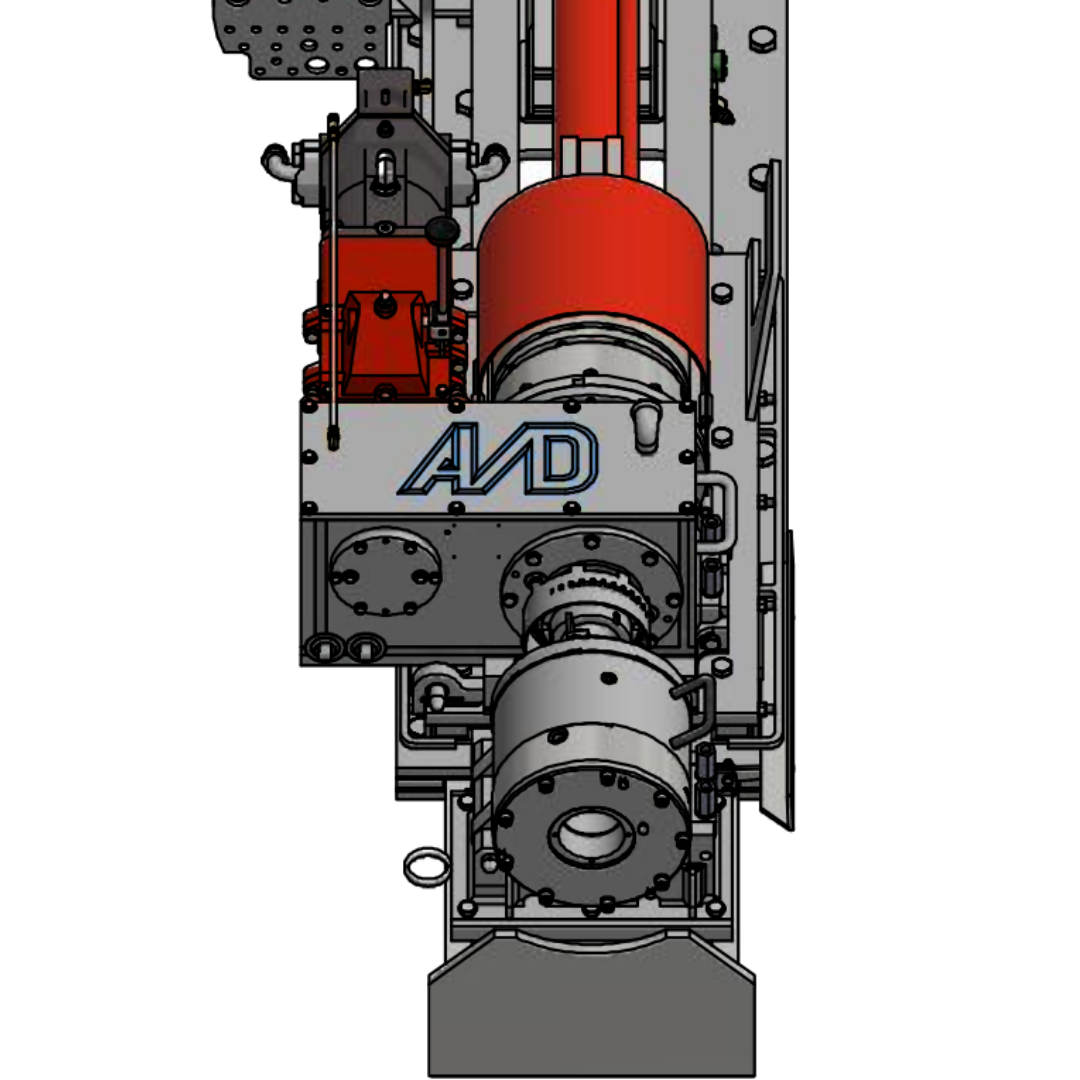

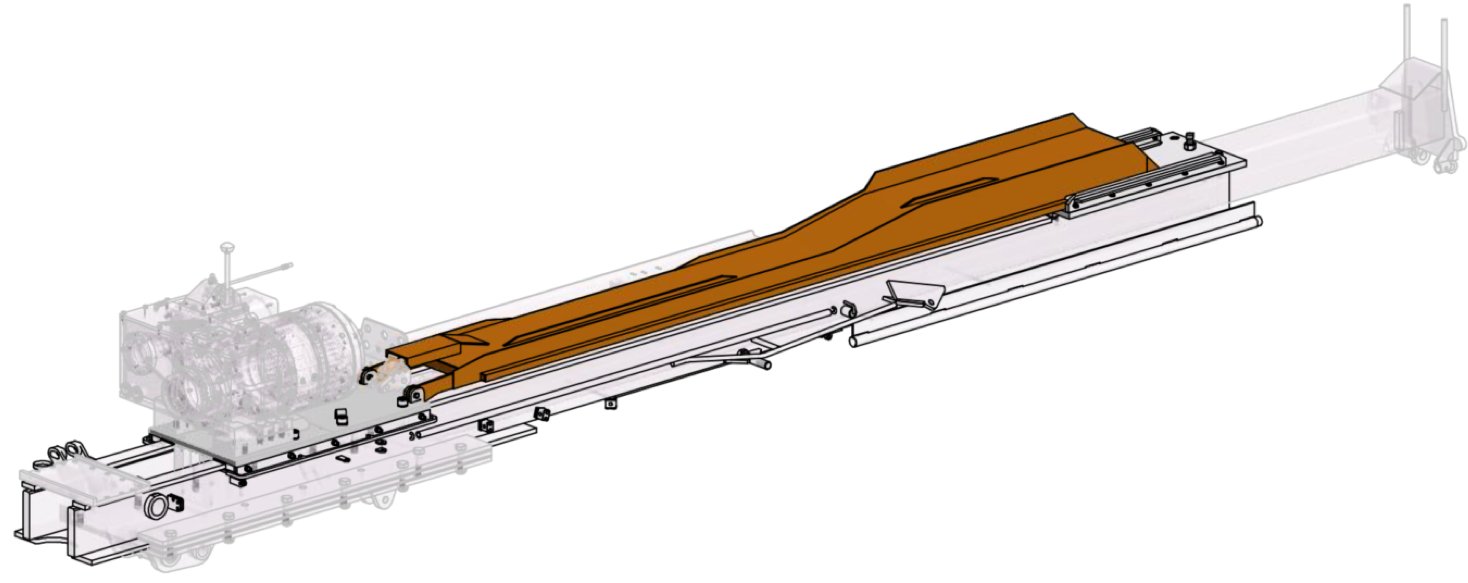

AVD "MA6" Drill mast

- Standard on VD3000 drill rig model.

- Tested at the depth of 1 524 m on N-size rods.

- Main cylinder of 3" diameter offers 31 800 lbs of pullback.

- Lightweight heliportable version available.

AVD "MA8" Drill mast

- Deep hole drill mast.

- Standard on VD5000, 6000 and VD8000 drill rig models.

- Record-holding tested depth of 3 400 m on N-size rods.

- Main cylinder of 4" diameter offers 56 600 lbs of pullback.

- Possibility to combine pullback to other systems to reach 100 000 lbs.

Drill mast options

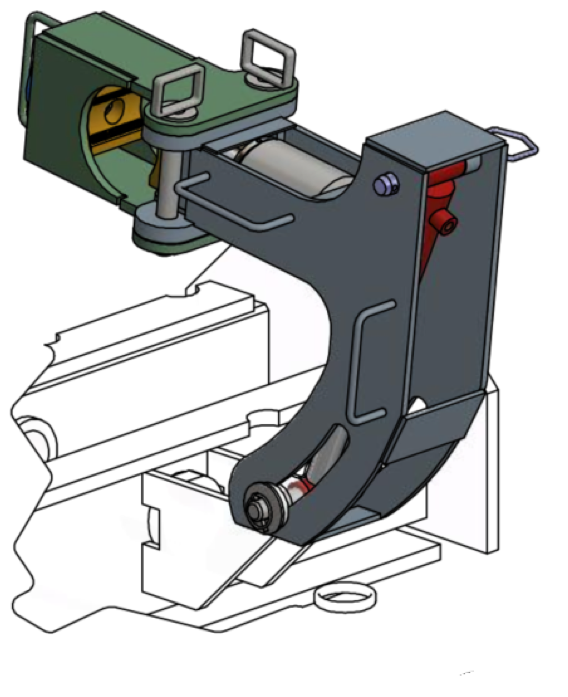

Remote locking mechanism for the mast extension

During the setup and removal of the drill rig, this option allows the driller to operate the locking mechanism from inside the drill, standing on the drill floor while industry standard requires climbing on the roof of the drill and insert a pin manually.

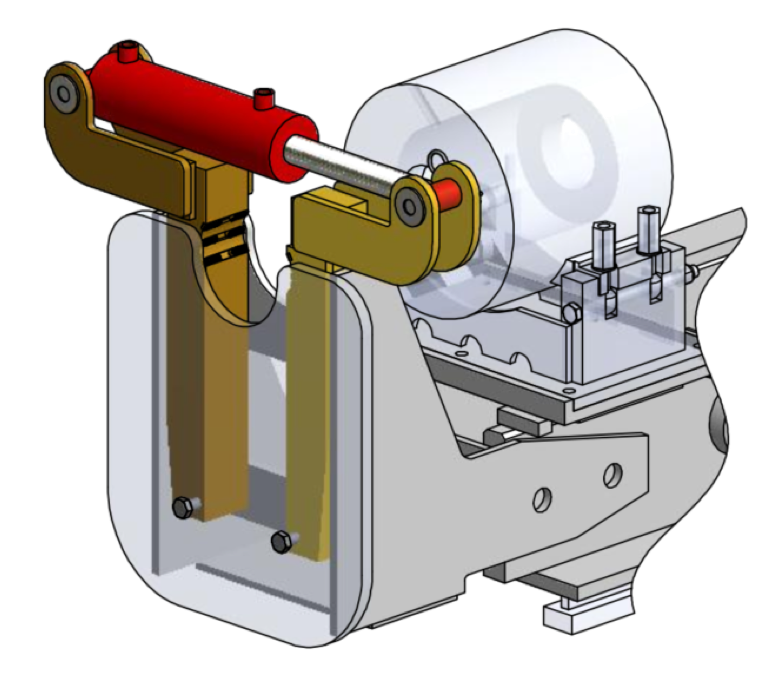

Casing breaker

This device is an auxiliary clamp mounted at the bottom of the mast and on a pivot. It could be used to break (undo) casing joints or other.

Casing clamp

This system is a fixed jaw mounted at the bottom of the drill mast that allows to hold the casing when needed.

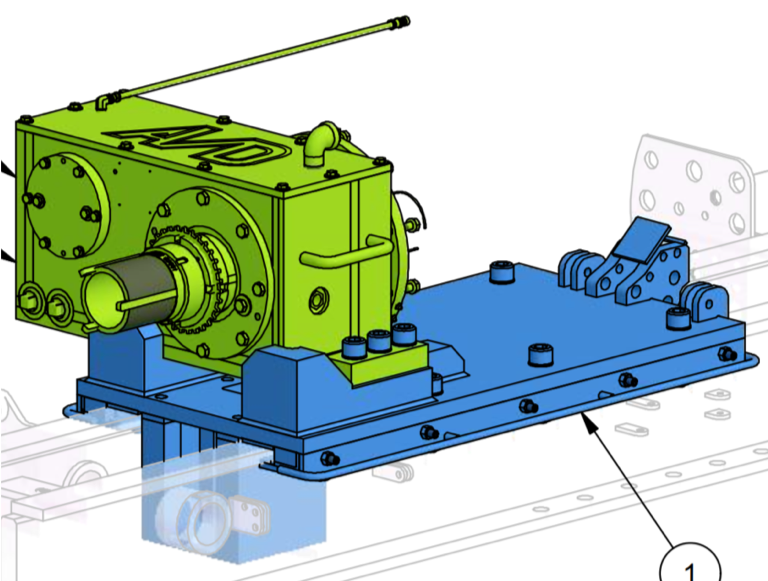

HD Bolted drill head casing and mast table

This new fastening system has the effect of increasing structural robustness of the assembly in order to reduce the maintenance required.

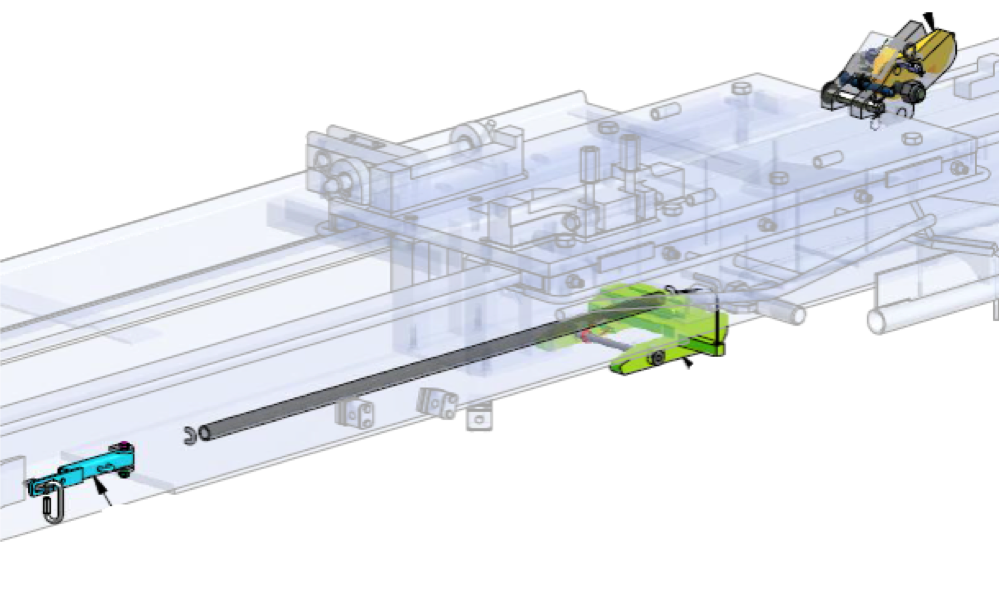

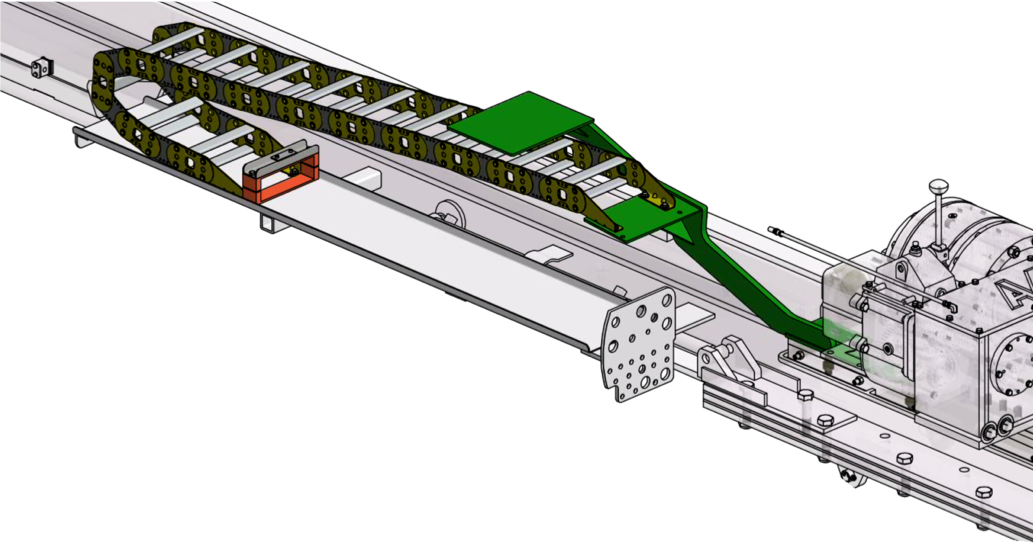

Gortrac™ hydraulic hose carrier system

This hydraulic hose carrier and support system significantly reduces the maintenance required on the hydraulic hoses, increases safety and reduces the risk of leaks.

Integral rod support system.

This integral rod support system eliminates potential pinch points and makes drillers' work easier by increasing ergonomics.